Employee safety is one of the most important factors when operating X-ray equipment. Prolonged or intense exposure to X-rays can lead to serious health risks, including radiation burns and acute radiation syndrome. The critical nature of X-ray exposure is why there are so many rules and regulations at federal, state, local, and organizational levels.

In this article, we’ll cover some of these rules and regulations and how to maintain compliance.

Table of Contents

Rules & Regulations

If your organization plans to use X-ray equipment, you need to research your state’s current regulations, which provide registration, renewal, record keeping, and surveying requirements.

These regulations will vary by state, city, and organization, so always ask your local authorities or professional which rules apply to you.

We’ll broadly discuss some of these regulations below.

Obtaining an Import License

Some countries, such as Mexico and Brazil, require an import license for each import of X-ray equipment. Ask your forwarder or customs broker if your country has those requirements. Please note that the licensing process can take months (usually three to six) before they’re accepted, so plan accordingly.

Registering Your Equipment

Most states require that you register your X-ray equipment. If you are considering buying XRD, you can find analytical X-ray regulations per state here. Some states require registration before purchasing, shipping, or installation, while others don’t. That’s why it’s important to check the rules and regulations before you purchase any equipment.

Generally, you would register your equipment online with your state’s Public Health or Environmental Protection divisions. Just go to your state’s website and find their Public Health or Environmental Protection sub-page, fill out and submit the form, and pay the registration fee, which varies from state to state.

If you don’t see your state listed on ASTR’s website, check with a state official because requirements may change.

Additionally, you may have to renew your registration every few years—when you apply for the initial registration, a representative will let you know. If you buy another X-ray tube or X-ray machine, you will need to file an amendment to your existing registration.

Local Inspections

Depending on your state, an inspection could be part of the registration process. These inspections will be performed in person or by submitting paperwork. Each state has requirements on how often these inspections should be performed after registration.

For example, in Michigan, analytical X-ray equipment has to be inspected within 12 months after registration and every three years thereafter, while mammography machines have to be inspected annually. Always check with your local department to see how often your equipment should be inspected, and always keep a record of when your inspections occur.

Signs & Labels

Next, you will need adequate signage that marks which areas within your building or facility that will be exposed to radiation. These signage requirements vary among states. Some common examples of signage include:

- CAUTION X-RAY: This yellow-and-black label is typically posted in the X-ray equipment room and on the entry door.

- NOTICE TO EMPLOYEES: This sign is usually white with a bolded ‘Notice to Employees’ headline. The rest of the sign includes state-specific regulations for radiation control. You can find this sign (along with posting requirements) on your state’s Department of Health Services website. Generally, these signs are posted in any restricted areas within the building or any areas that may be exposed to radiation.

Training

In most states, only trained personnel are allowed to operate X-ray equipment. However, it’s best practice to train anyone on equipment use, regardless of state requirements. You can ask your state’s health department if a training certificate is required. Keep comprehensive documentation of any training, including employees’ names and the date of the training.

Record-Keeping

Every time you train an employee, survey for leakage, and receive an equipment inspection, you need to record it. Records can be in writing or digital. In states that require record-keeping, you will be assigned a record-keeping book by a radiation safety officer or other qualified person. Your state will also have specific rules and regulations regarding record keeping and retention.

Surveying for Leakage

Depending on your state, surveying may be required every period, quarter, or year.

When you survey, use the surveymeter around the entire perimeter of the enclosure, as well as the top and bottom.

It’s also recommended that you test for X-ray leakage when operating your equipment. Most X-ray equipment comes with an enclosure designed to prevent leakage, but knowing the exact level of leakage can help reassure operators and technicians.

Running X-ray equipment outside of the enclosure is allowed in many countries as long as a safety area is created. A radiation safety officer or other qualified person must create a safety area by measuring the radiation level before operation. Ask your local authorities or professionals if there are any specific rules on using X-ray equipment without an enclosure.

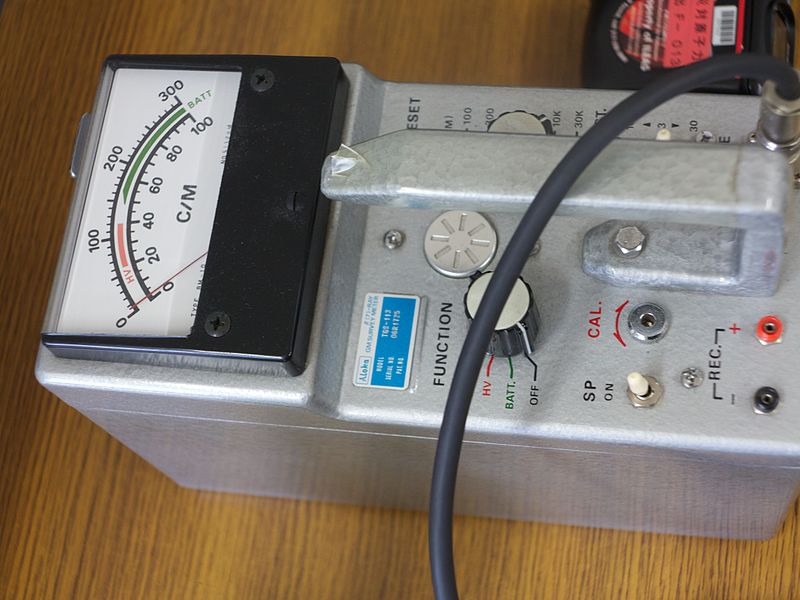

Surveymeters

You can purchase many different types of surveymeters, including Geiger counters, Pancake sensors, and Ion chambers. Each product will have different characteristics, such as energy range, accuracy, and sensitivity, so it’s important to know which technology is suitable for your purposes.

Additionally, the measurement units vary from country to country. For example, “mrem” (mili-rem) is used in the U.S., while μSv (micro-sievert) is popular in other countries. Most meters do not switch between these units. Confirm which unit is used in your country before purchasing a surveymeter.

Geiger Counters

Geiger counters are extremely sensitive to low levels of radiation and can detect different radiation types, including alpha, beta, gamma, and X-rays, and provide immediate feedback. However, they do not offer detailed energy information about the radiation, making them less suitable for identifying specific isotopes or detailed energy levels.

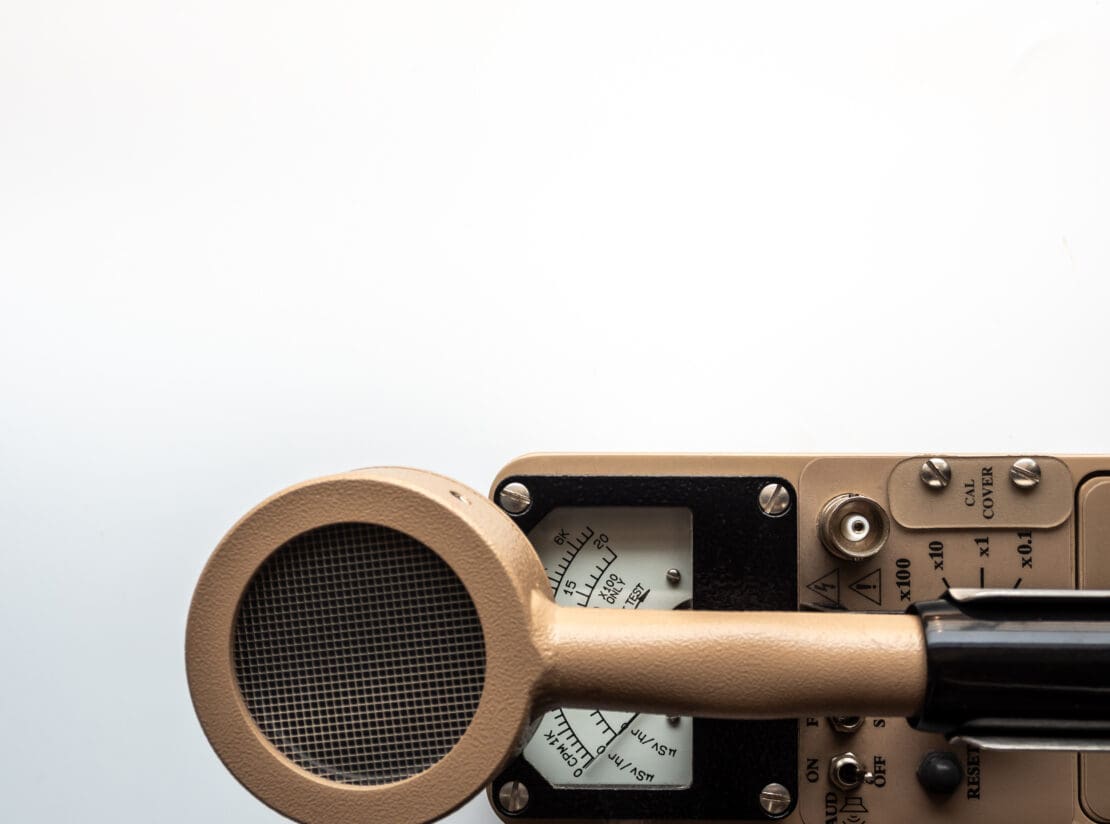

Pancake Sensors

Pancake sensors are technically a type of Geiger tube but with a larger, flat shape. They can be good for scanning over larger areas and can also detect different types of radiation, but they’re larger and less portable than traditional Geiger tubes.

Ion Chambers

Ion chambers provide highly accurate measurements and are suitable for both very high and very low radiation fields. These are usually chosen for analytical X-ray purposes because the X-ray energy levels can be low (around 5.4 keV, if Chromium) and will be detected by this type of surveymeter. However, as mentioned earlier, you should always confirm the energy range in the specification sheet before you purchase any surveymeter.

Surveymeter Calibration

You should always calibrate your surveymeters annually to ensure accuracy. Your surveymeter manufacturer will provide more specific information on calibration tolerances and a recommended frequency.

Human Dose Limits

When testing for leakage, there is a human dose limit you don’t want to exceed. This limit varies in different countries. The United States has two limit categories: occupational and public. The occupational category has three subcategories: adult, minor, and embryo/fetus.

- Adult Occupational Limit: 5,000 mrem per year (whole body), 15,000 mrem per year (eye lenses), and 50,000 mrem per year (skin and extremities).

- Minor Occupational Limit: 500 mrem per year (whole body), 1,500 mrem per year (eye lenses), and 5,000 mrem per year (skin and extremities).

- Embryo/Fetus Limit: Should not exceed 500 mrem per year.

- Non-Occupational/Public Limit: 100 mrem per year (whole body)

You can find more information on the NRC’s website.

Ask About Our Surveymeter

Pulstec is committed to helping our customers stay safe while using our equipment. If you recently purchased one of our products or have existing X-ray equipment, please contact us today to learn more about our new surveymeter.