The Answer to Precise Residual Stress Mapping

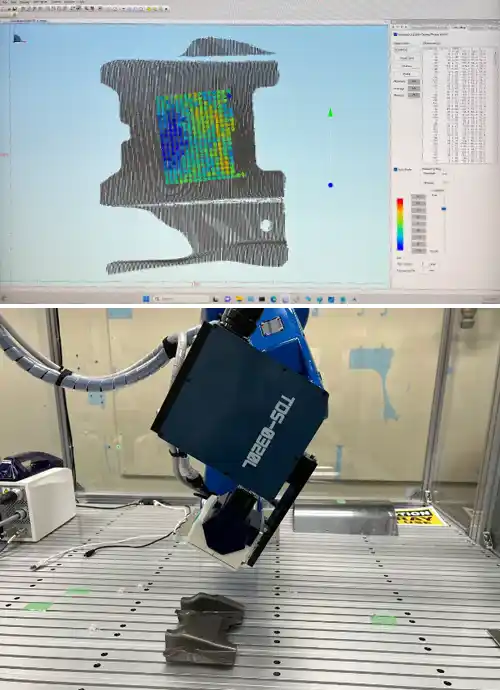

Robotic Residual Stress Mapping System With 3D Scanner

The Answer to Precise Residual Stress Mapping

Pulstec’s Robotic Stress Mapping System is an advanced system that integrates a robotic arm equipped with an X-ray stress analyzer and a 3D scanner. We designed this system to perform precise stress mapping on a variety of materials, regardless of their shape.

The 3D scanner first captures the geometry of the sample, including curved surfaces, allowing the robot to precisely target and measure stress distributions at desired areas. This seamless integration of scanning and analysis capabilities ensures accurate, efficient, and comprehensive stress evaluation, which is ideal for research purposes and high-demand industrial applications.

XRD Stress Analyzer:

3D Scanner:

Robot:

Motorized Rotation Stage:

Shielding Box/Robot Enclosure:

PC & Monitor

Disclaimer: The PC features software for robot mapping function, TDS operation, μ-X360J operations, and mapping display.

Power Supply:

Brochure for the Robotic Residual Stress Measuring System With 3D Scanner

Learn MoreWe know our technology is leading the industry. Allow us to show you the benefits of working with Pulstec. Contact us today for a free demonstration on-line or at your facility.